July2020:

High Accμracy Project

Press Release July 2020

Hi-Accµracy: imec, NeuDrive and IAP collaborating to advance ESJET QD-LED fabrication

The H2020 funded, Hi-Accµracy project aims to product printed flexible, hi-resolution displays, which are more sustainable and lower cost to open up exciting, new markets for display technologies. Printed displays require extraordinary levels of accuracy in the deposition of device features, and project Hi-Accµracy will utilise a variety of deposition methodologies including ESJET printing (Electrostatic Jet Printing).

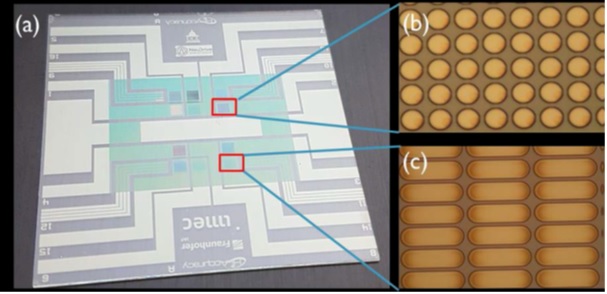

In order to test the concept of QD-LED fabrication by ESJET printing, imec designed, and NeuDrive fabricated, test substrates in circular and super ellipse shapes with a pixel definition of 338 pixels per inch (ppi) to 3175 ppi, and aperture ratio of 12 % to 75%. A third partner, IAP, will now develop a repeatable and scalable QD-LED fabrication processes using ESJET printing onto these substrates.

Figure 1. (a) The fabricated rigid glass substrate for QD-LED ESJET printing process development. (b) The close-up of active area, with circular PDL openings. (c) The close-up of active area with super ellipse PDL openings.

To learn more and access the full programme please visit: https://www.horizon-europe-community.at

To learn more about these innovations, as well as details about the partner organisations, visit www.hi-accuracy.eu This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 862410. ENDS